Indoors or out, Nicole Chu, M.Eng. ’19, loathes breathing in carbon monoxide, sulfur dioxide and other volatile organic compounds. They’re bad for everyone’s health.

Since last August, Chu has been fabricating the foundation of a wearable, personalized air quality monitoring device, by using nanotechnology, photolithography and other tools at the Cornell NanoScale Science and Technology Facility (CNF).

“The end goal is to create small, personalized sensors that communicate to a smartphone and deliver data,” said Chu, who explained that air quality monitoring systems now on the market lack sensitivity and tend to be expensive.

“Many people are unaware of just how polluted the air is around them,” she said.

Indoor air can be two to five times more polluted than outdoor air, Chu said, based on data provided by the U.S. Environmental Protection Agency. On average, Americans spend around 90% of their time inside, which leads to prolonged exposure to harmful chemicals such as nitrogen dioxide, ammonia and other volatile organic compounds.

“In this project, we’re hoping to maximize the sensors’ ability, bring down costs and use the technology for other applications and other flexible devices,” she said.

Chu – like other students in Cornell’s Materials Science and Engineering Master of Engineering (M.Eng.) program – conducted this hands-on project matched with a nearby small company. Chu was matched with FlexSurfaces in Binghamton, via the Cornell Center for Materials Research’s Industrial Partnerships program and funded by Empire State Development.

“The projects integrate materials science, engineering and design and provide students with an immersion and fast-track, in-depth experience figuring out tools or trying out solutions – all while learning material properties, synthesis and processing,” said Alex Deyhim, adjunct professor of materials science and engineering and associate director of the M.Eng. program.

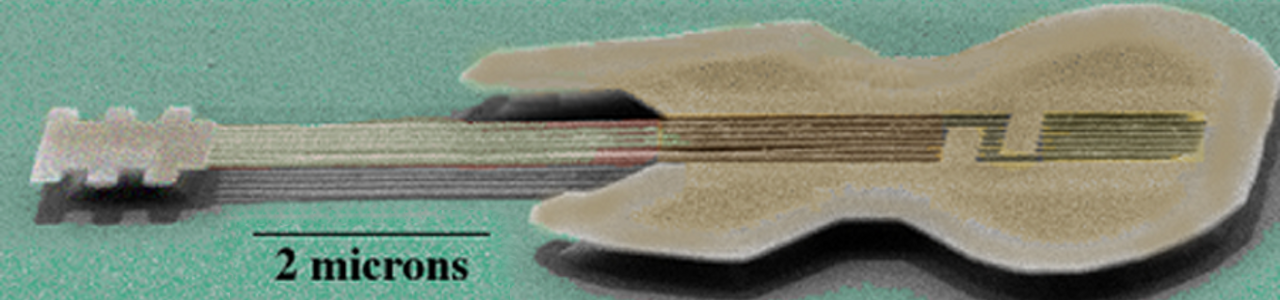

At the heart of the flexible design Chu created for FlexSurfaces is a substrate material made from a heat-resistant polymer on which sensors – nano-fabricated, interlocking microelectrodes, which she developed – can be imprinted via photolithography.

“The most challenging part of my project was becoming familiar with the process and clean room tools,” said Chu. “I had no prior experience with these and it took a little practice to get some of the skills in the clean room right.

“Aside from the training by the CNF staff, I was for the most part on my own in there,” she said. “It took a little time and I trashed a few samples, but I soon became comfortable using all the tools and machines I needed.”

In two semesters, Chu created a solid process for producing the heart of the devices on flexible substrates. So far, early tests show that Chu’s microfabricated electrodes worked well, detecting volatile organic compounds.

“We ran into a few technical issues when attempting to transfer our devices from glass onto flexible substrates,” she said, “but we were able to figure out each problem as it arose and I was able to fabricate hundreds of devices for the company to test further.”